Software

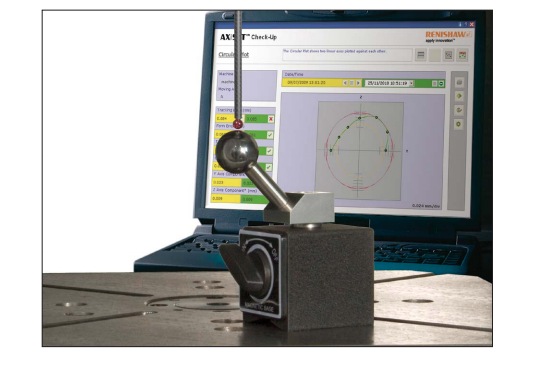

AxiSet™ Check-Up

AxiSet™ Check-Up, is a new system that offers fast, automated health checks for multi-axis machine tools.

About AxiSet™ Check-Up

Compatible with common formats of 5-axis and multi-tasking machines, AxiSet™ Check-Up provides machine users with a fast and accurate health check of rotary axis pivot points. Alignment and positioning performance checks are carried out rapidly to benchmark and monitor complex machines over time.

With its probing macro software and a dedicated calibration artefact, it provides graphical representations of multi-axis machine performance. It makes PASS or FAIL decisions based on defined tolerances, and allows performance to be tracked over time, using history and comparison functions. All of which helps to identify poor machine alignments and geometry due to machine set-up, collisions or wear.

Performance analysis is reported graphically via Microsoft® Excel®, compared against user defined tolerances and stored for historical comparison. All results can be printed in a standardized report via Microsoft® Word®.

Benefits of AxiSet™ Check-Up

•Measure and report multi-axis machine performance in a matter of minutes.

•Capability to detect and report errors in rotary axis centre of rotation (pivot points) that are critical in 5 axis interpolation.

•Fully automated probing tests provide accurate and consistent results, avoiding introduced errors associated with manual tests.

•User defined test angles allow machines to be tested at critical orientations.

•Tolerance functions increase confidence before critical features are machined.

•History and comparison functions allow performance to be tracked over time, allowing trends to be monitored and maintenance scheduled.

•Graphical reports combined with tolerance checking quickly identify changes in performance due to collisions or setting errors.

•All graphical plots are available in printed reports for record keeping and distribution.

Tool setting software

Tool setting software for contact and non-contact tool setting probe systems.

•Set tool length and/or diameter

•Manual or automatic (programmed) positioning

•In cycle broken tool detection (where applicable)

About Renishaw tool setter software

Renishaw tool setting software allows you to set tool length and diameter offsets for single point and multiple point tools, perform in-cycle broken tool detection and manual or automatic (programmed) positioning.

EasyProbe - probe software for machining centers

Produce simple and fast job set-up and measuring routines with minimal programming skill.

•Simple programming

•Work offsets updated for accurate component positioning

•Results and errors stored in macro variables

About EasyProbe software

EasyProbe software cycles are designed for use by machine tool operators for simple job set-up and measuring tasks on machining centres. The software can be easily configured, using a supplied install utility, to suit the machine tool configuration.

Probing can either be through use of the machine tool handwheel / jog function with cycles run via manual data input, or through cycles written into a part program and run automatically.

Feature and benefits

•Simple programming - EasyProbe cycles require little programming skill to achieve simple probing tasks

•Part set-up - work offsets can be updated for accurate component positioning

•Measurement results and errors are stored in a macro variable list

•Angle find macro can be used to update a 4th axis or enable G68 co-ordinate rotation

Inspection Plus - software for machining centers

Macro software incorporating vector and angle measure, print options and an extended range of cycles.

•1-touch or 2-touch probing options

•Tool offset compensation

•Output data into accessible variable stack

About Inspection Plus

Inspection Plus provides an integrated package of macro software that includes vector and angle measure options, print options (controller dependent) and an extended range of cycles.

Inspection Plus includes an SPC cycle, 1-touch or 2-touch probing options, tool offset compensation by percentage of the measured error, and output of data stored into an accessible variable stack.

Features and benefits

Compared to the more basic Inspection software:

•All cycles in one integrated package

•Improve output data storage and report formatting

•Extra cycles - angle corner find, internal boss / web, vector probing, angled web / pocket measure and stock allowance

•Feature-to-feature distance measurement

•Optional 1- or 2-touch probing - one touch probing on controls with high speed skip, whilst two touch cycles offer greater accuracy where a high speed input is not available

•Protected positioning - stop the machine in the event of an unexpected collision

•Tolerances on size and position, applying an alarm if material is out of tolerance

•Ensure process stability by specifying a band around the nominal size where no error compensation is applied

•'Damped' corrections (% of error feedback) to avoid overshooting the nominal size

•SPC feedback based on trend analysis and average readings

•Apply correction factors that take account of known process characteristics

•Results can be printed or written to a file

Inspection software for machining centers

Basic macro software for Renishaw component setting and inspection probes for machining centers and lathes. Compatible with:

•Machining centres

•Turning centres

•Multi-axis turning centres

About macro based programming

Renishaw's Inspection software comprises a set of macros that control probing motion and point data manipulation, measuring a range of common component features with input of a few parameters.

Tool and work offsets can be updated automatically based on measured dimensions. On completion of each measurement cycle it is possible to print out the results.

Some capabilities may vary by an individual controller.

Users requiring a more comprehensive set of probing cycles may find Inspection Plus a more suitable solution.

Inspection software for machining centers

Available measurement cycles include:

•X or Y or Z single surface measure

•web/pocket

•four point bore/boss

•external corner

•angle through two bores/bosses (Fadal only)

Inspection software for turning centers

Renishaw Inspection software for turning centres offers macros for:

•single point (radial) measurement

•two-point (diameter) measurement

•rib/groove measurement

•single Z-surface measurement

Inspection software for multi-axis turning centers

•horizontal and vertical head orientations

•X, Y and Z single surface measure

•bore/boss

•web/pocket

•C-axis find

Renishaw OMV

PC-based, on-machine component inspection and verification software for machining centres.

•Inspect geometric features and free-form surfaces

•Multi-axis machine support

•On-screen simulation for program prove-out

About OMV

Renishaw OMV allows you to check complex machined parts against the CAD model, without them being removed from the machine. It gives confidence that the part you see conforms to the CAD model from which it was made.

By verifying your part on the machine tool, you can save valuable production time - eliminating wasted time on set-up for rework.

Latest functionality

Adding to the comprehensive functionality available in previous versions, Renishaw OMV 2013 R1 SP2 introduces:

•'Probe and Parameters' item - allowing fast and simple programming of probe changes and the adjustment of associated parameters

•CAD compatible export- export measurement information relating to geometric features and surfaces in a CAD compatible format for use in re-engineering applications

•On model dimensioning in Renishaw OMV ProDimensioning - create labels to display measurements on the CAD model. This functionality now covers linear, angular and radial dimensions. (Renishaw OMV Pro only)

•Section Groups - directly measure cross sections through a component, either through all surfaces, or through selected areas of the cut plane. (Renishaw OMV Pro only)

For further information on the new features and functionality available in the latest release, see the Renishaw OMV - on-machine component verification software: version 2013 R1 SP2 flyer. Alternatively for an overview of the full functionality provided by the software, see the Renishaw OMV on-machine 3D verification data sheet.

Easy programming

Renishaw has also simplified the programming process; now you can work from your office PC to create probing routines direct from the CAD model, including measurement of geometric and free-form features. No direct PC connection is required to run the generated program on the machine tool; the points collected on the machine can be read back into the software using floppy disk, Ethernet, or RS232. Renishaw OMV can also be used to give immediate feedback on the object tolerance by displaying colour-coded points on the CAD model.

Powerful reporting

Simple graphical reports and an on-line results display, give you an instant indication of the match of your part to the CAD model, allowing instant Go/No Go decisions.

Renishaw OMV also features comprehensive best fit and alignment functions to minimise the set-up time required when returning parts to the machine after an external process. In most cases, a rough set-up of the work co-ordinates is enough to give accurate, repeatable results.

Productivity+™ - PC based probe software for machining centers

The RTS uses the RMI-Q radio interface for multiple probe use.

Interactive programming of inspection routines, tool setting

and machine updates.

•Comprehensive set of measurement routines

•Logic statements for on-machine decision making and

process control

•Detailed reporting of inspection and updates

About Productivity+™

Productivity+ is a PC based software solution providing an easy-to-use platform for incorporating simple measurement functionality and more advanced in-process intelligence into machining programs. It can simplify a wide range of measurement and process control tasks, such as component set-up and part verification, and aids process development in the following key areas:

•Predictive process setting - performing simple tests to ensure that a machining process will be successful

•Active in-process control - using the probe to measure features and update machining process based on the results obtained

•Informative reporting - providing information about the in-process state of a component, and about the decisions that were made when producing it

Productivity+ creates programs which run entirely on the machine tool, including all the calculations, updates and logic which are needed - so no external PC is required to process measurement data.

Productivity+ provides full multi-axis support for vertical and horizontal machining centre configurations.

Productivity+™ provides

Point-and-click feature selection - based on a wide range of CAD models

Tool setting - speed up tool change and avoid damaged tools (Renishaw tool setting macros required on the CNC)

Part set-up and inspection - auto-correct machining cycles

Intelligent decision-making - allowing active, in-process control with program adjustments and machine updates

On-machine verification - reduce production time

Probe cycle programming - PC based solution, therefore avoiding machine downtime

Program verification - to increase confidence and reduce risk of machine or probe crash

Process tracking - with the addition of Renishaw CNC Reporter

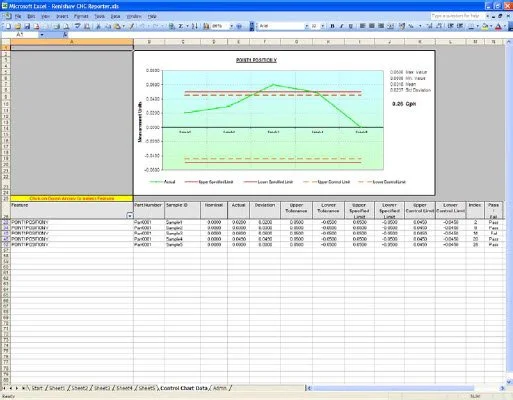

Renishaw CNC Reporter

Display and process inspection results from the Productivity+™ software suite.

•Colour coding provides instant Go/No Go decision

•Part conformance tracking for machine condition monitoring

•Complementary application to analyse large volumes of historic data

About Renishaw CNC Reporter

Renishaw CNC Reporter is a PC-based statistical analysis tool designed to interrogate measurement data returned by Renishaw probing software.

Displaying data in printable tabular and graphical formats, the application displays actual measured data plus deviation from nominal, and uses colour coding to indicate adherence to tolerance at individual feature and component level, providing an instant indication of part conformance.

A complementary application, Data Manager, installs alongside Renishaw CNC Reporter. This application provides the ability to further analyse large volumes of toleranced, multi-feature inspection data that has been previously processed using CNC Reporter.

Both CNC Reporter and Data Manager operate within the Microsoft Excel spreadsheet package, providing a comfortable and familiar operating environment, coupled with the capability to easily configure custom report templates.

Renishaw CNC Reporter is intended for use with a single CNC machine tool. If there is a requirement to simultaneously import data from multiple machine tools, multiple seats of Renishaw CNC Reporter are required.

Features and benefits of Renishaw CNC Reporter

Highly visual data display in an easy to understand format

Easily configurable in a familiar Microsoft Excel environment

Colour-coded reports for instant GO/NO-GO decision

Feature tracking and control plots allow processes to be monitored over time

Complementary Data Manager application for the historical analysis of large volumes of toleranced inspection data

· Export data to external SPC and other packages for additional analysis

Renishaw probing software

Renishaw CNC Reporter is compatible with the output from the following Renishaw probing software applications:

•Productivity+ Active Editor Pro

•Productivity+ GibbsCAM plug-in

•Inspection Plus *

* configuration by Renishaw applications engineers will be required before results data from Inspection Plus can be imported directly into CNC Reporter

NOTE: Some NC control platforms which are compatible with these software packages do not support the output of inspection report data and are therefore not compatible with Renishaw CNC Reporter.