Toolsetters

NC4 Non-Contact Laser

A range of non-contact tool setting and broken tool detection systems for machining centres.

Available in separate (modular) and fixed (compact) formats to suit a range of machine configurations.

About NC4

The NC4 allows fast, non-contact tool setting and tool breakage detection on a variety of machining centres. Available as fixed system and separate system variants, the NC4 incorporates the unique MicroHole™ protection system and the innovative failsafe PassiveSeal™, maintaining IPX8 environmental protection.

Recently introduced to the fixed NC4 range are the F95, F115 and F230 compact series, offering new performance standards in small packages, using the same transmitter and receiver units as the NC4 separate and modular fixed systems.

With all NC4 systems, precision optics are supplied as standard. These enable the compact series to achieve un-surpassed performance in a unit particularly suited to small machines and machines where space is at a premium.

The NCi-5 interface is required for use with NC4 and other non-contact tool setting systems.

NC4 Features and benefits

Compact design is ideal for machines previously unsuitable for large non-contact systems

•Precise tool length and tool diameter measurement

•Only 1 M-code required

•NC4 measures and detects tools of Ø0.03 mm or larger (dependent on separation and mounting)

Software for NC4

Renishaw's macro-based non-contact tool setting software is used to easily program tool setting and broken tool detection routines.

High precision tool setting arms for lathes and grinding machines

Time is money, and time spent setting tool dimensions then manually entering tool offset data is time that could be better invested in machining. Tool setting and broken tool detection are vital if a high level of confidence in product quality and unmanned machining is to be maintained

HP arm series

· HPRA: High precision removable arm

'Plug-in' arm which is manually located in the machine when tool setting is performed, and then removed once the process is completed.

· HPPA: High precision pull-down arm

HPPA uses an innovative rotary device which automatically locks the arm into a repeatable kinematic location, with no additional adjustment or locking device required.

· HPMA: High precision motorized arm

An electrically powered arm. Rapid actuation allows in-process tool setting and broken tool detection without the need for operator intervention.

· HPGA: High precision generic arm

A highly repeatable motorized solution for tool setting and workpiece inspection with improved robustness and adaptability on grinding machines and CNC lathes.

HP arm system kits for lathes (HPRA, HPPA, HPMA)

HP arm kits comprise:

•Tool setting arm

•RP3 probe

•Rear exit base and stand

•TSI 2 or TSI 3 interface

•User's guide

HP arm system kits for grinding machines and lathes (HPGA) HP arm kits comprise:

•Tool setting arm

•MP250 or LP2 probe

•Side exit hub and base

•HSI and TSI 3 interface

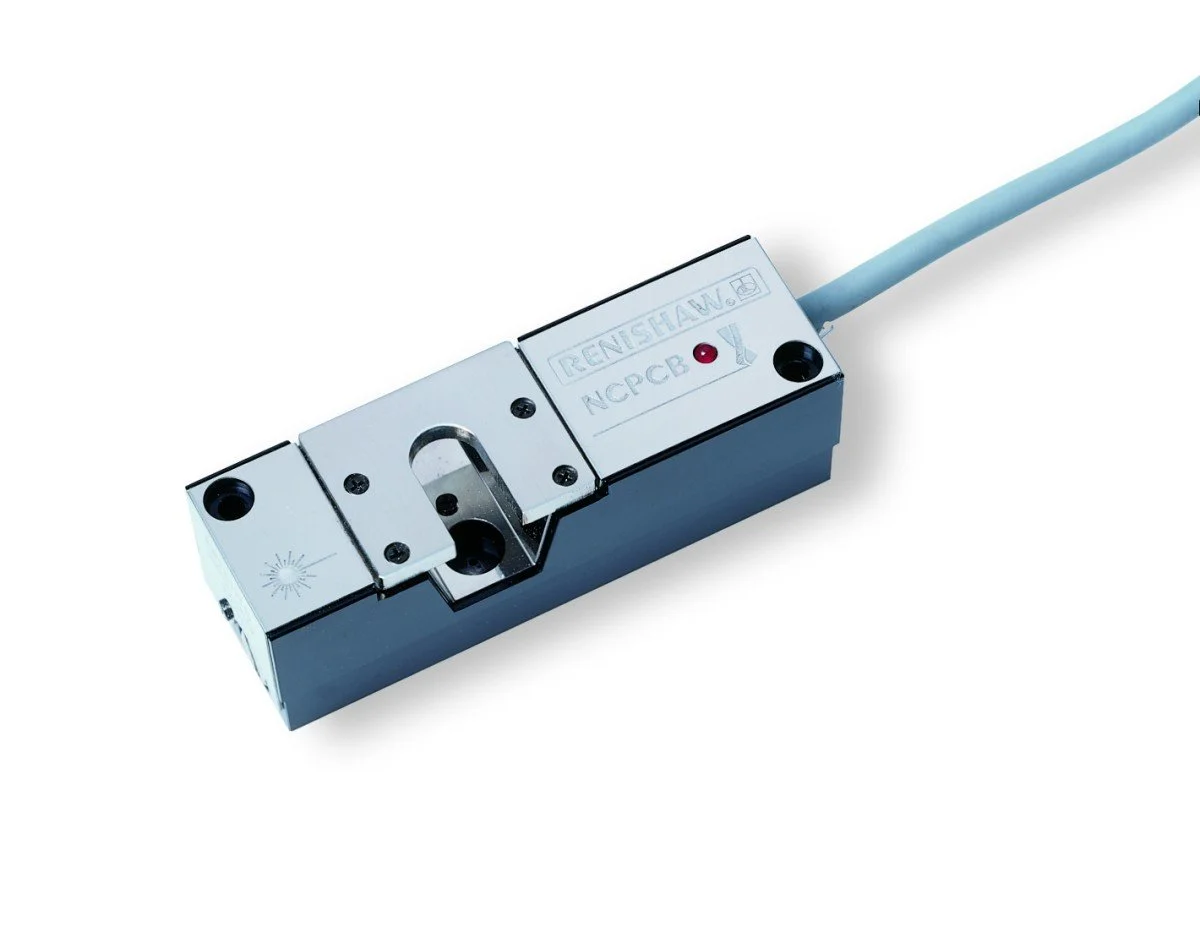

NCPCB

The NCPCB (non-contact tool setter for PCB drilling machines) is part of the Renishaw family of tool setting probe systems.

The NCPCB tool setting device is used for rapid tool setting, tool wear monitoring, runout checking, and tool breakage detection on PCB drilling machines in one simple compact unit.

About NCPCB

The NCPCB is an affordable, simple to install system that will:

•Reduce your non-value downtime

•Reduce your component scrap counts

•Increase your machine efficiency

•Increase your process capability

NCPCB Features and benefits

•Compact; it measures just 80 mm (long) x 25 mm (wide) x 27 mm (tall)

•It has an integral in-built air blast capability for optics/tool cleaning

•Allows diameter measurement of tools as small as 0.1 mm

•Use on multiple spindle machines capable of 250,000 rpm

•Excellent response times which allows repeatability of 0.5 µm

OTS Contact Tool Setting Probe

OTS cableless optical tool setting and broken tool

detection for vertical machining centres.

The OTS can be used as part of a multiple probe or

twin probe system, either with a second OTS (e.g. on

machines with twin pallets), or with a suitable inspection probe.

About OTS

For broken tool detection and rapid tool length/diameter measurement use the OTS, Renishaw's first tool setting probe with optical transmission. The robust, compact and cable-free design allows freedom of table movement, ideal for twin pallet or rotary table machines.

The OTS is available in two versions, one with 1/2 AA batteries and the other with AA batteries. This allows the use of the same battery type in the OTS as that of the spindle probe.

The OTS uses the OSI with OMM-2 optical interface for multiple probe use, the OMI-2T optical interface for twin probing (or single probe use) and the OMI-2 for single installations only.

OTS Features and benefits

Optical tool setting probe - no cables

•Compact table mounting, ideal for twin pallet or rotary table machines

•Precise tool length and diameter measurement

•Automated updating of tool offsets

Software for OTS

Renishaw tool setting software allows you to set tool length and diameter offsets for single point and multiple point tools, perform in cycle broken tool detection and manual or automatic updates.

RP3 Feature and benefits

•1 µm repeatability

•Compatible with the full range of Renishaw M4 styli

•Standard fit HP series toolsetting arm (HPRA, HPPA and HPMA)

•Flexibility - OEM kit available for OEM installations

•Large 9° of over-travel - increases the durability of the probe.

RP3

RP3 tool setting probe for HPRA, HPPA and HPMA arms.

The RP3 is also suitable for OEM installation into purpose-built holders.

About RP3

The RP3 probe is suitable for OEM installation into purpose-built holders, or for use with Renishaw's automatic or manual tool setting arms.

A robust 5-way probe for tool setting and some inspection applications. Advanced design has produced an extremely small probe with 1 µm repeatability and large over-travel.

The MI 8-4 or HSI interface is required for use with the RP3 hard-wired probe.

RTS contact tool setting probe

RTS for cable-free radio tool setting and broken tool detection on CNC machining centres.

When combined with RMI-Q, the RTS can be used as part of a multiple probe system with either additional RTS and/or radio inspection probes.

About RTS

For broken tool detection and rapid tool length/diameter measurement use the RTS, Renishaw's first tool setting probe with radio transmission. The robust, compact and cable-free design allows freedom of table movement, ideal for twin pallet or rotary table machines.

The RTS uses AA batteries.

The RTS uses the RMI-Q radio interface for multiple probe use.

RTS Features and benefits

Rapid measurement of tool length and diameter on a variety of machine tools

•Cable free for unrestricted machine movement and ease of installation

•Trigger Logic™ for quick and easy setup

•Delivers interference free transmission through the use of frequency hopping spread spectrum (FHSS)

•Globally recognized 2.4 GHz waveband - compliant with radio regulations in all major markets

Software for RTS

Renishaw tool setting software allows you to set tool length and diameter offsets for single point and multiple point tools, perform in cycle broken tool detection and manual or automatic updates.

TRS2 non-contact broken tool Detection System

TRS2 non-contact broken tool detection system for machining centres.

A single-sided device featuring an integral laser transmitter and detector,

the TRS2 recognizes the presence of a rotating tool, typically in less than 1 second.

About TRS2

The new TRS2 is a cost-effective broken tool detection system. Its ToolWise™

electronics have been enhanced to make detection of small, dark tools more

reliable, saving time and money.

The unique tool recognition electronics determine whether a tool is present by

analyzing the reflective light pattern from the rotating tool. Random light patterns

created by coolant and swarf are ignored, eliminating the chance of failing to

detect a broken tool due to coolant obscuring the beam.

TRS2Features and benefits

•Cost effective and reliable

•Ultra quick detection - tool spends about 1 second in the laser beam

•Simple installation - only one small unit to install

•Simple set-up using specifically written software for TRS2

•Wide range of tools can be detected

TS27R contact tool setting probe

The industry-standard contact probe for tool setting and broken tool detection on vertical machining centres.

About TS27R

TS27R is mounted on the machine table. It enables the user to set tool length and diameter of rotating tools, and to carry out broken tool detection.

As with all Renishaw hard-wired probe systems, TS27R requires the MI 8-4 interface or HSI to convert probe signals into an acceptable form for the CNC machine control.

TS27RFeatures and benefits

•The standard tool setting probe for machining centres

•Compact table mounting

•Precise tool length and diameter measurement

•Rotating tools can be checked without wear to the tool or stylus

•Stylus is protected by a weak link, preventing probe damage in the event of a collision

Software for TS27R

Renishaw tool setting software allows you to set tool length and diameter offsets for single point and multiple point tools, perform in cycle broken tool detection and manual or automatic (programmed) positioning.

TS34 Contact Tool Setting Probe

Table-mounted tool setting probe for CNC machining centres

About TS34

The TS34 has been designed to supersede the MP4 tool setting probe.

The TS34 tool setting probe is table-mounted on CNC machining centers and is available with side or rear exit cable.

For tool length measurements and broken tool detection, the tool is driven against the probe’s stylus in the Z axis. Rotating tools can be set in X and Y axes for tool radius offsets.

The HSI interface unit processes signals between the probe and the CNC controller.