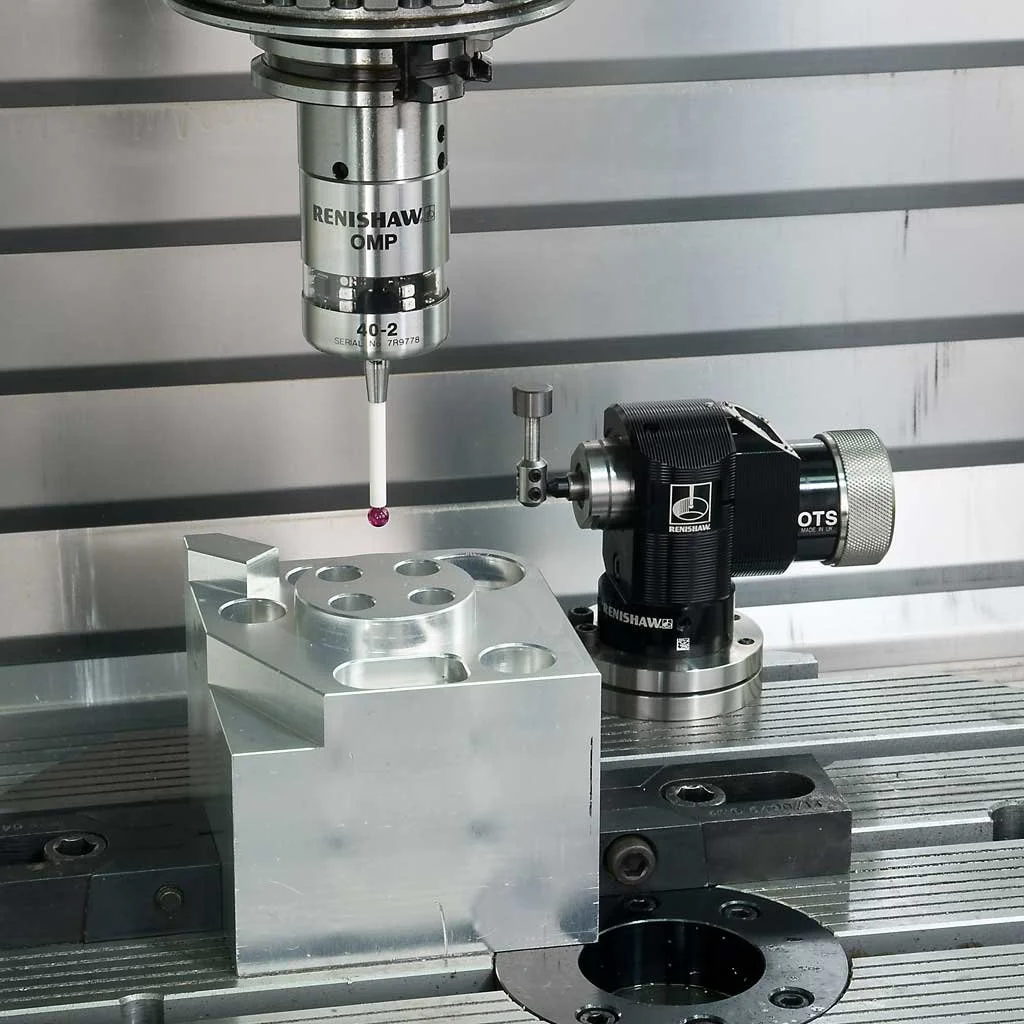

Probes for Machining Centers

OMP40-2 Compact Touch Probe

Spindle mounted optical transmission measurement probe with superior 3D performance. Use for Compact touch probe with optical transmission, ideally suited to small machining centers.

About OMP40-2

The OMP40-2 probe has been designed specifically to meet the demands of small machining centers and the growing family of high-speed machines fitted with small HSK and small taper spindles.

OMP40-2 is available with modulated transmission for use with OMI-2, OMI-2T, and OMM-2 receivers offering increased resistance to light interference.

OMP40-2 Feature and benefits

Ultra-compact - only Ø40 mm and 50 mm in length

Miniaturisation of electronics without compromising performance

Simplified installation - ideal for retrofit

Long battery life, minimal downtime, industry-leading economy

Shock and vibration resistant

OMP40-2 Software options

The following software packages can be used to program probing routines for work piece set-up and inspection on CNC machining centers.

EasyProbe - entry-level package for simple work piece set-up.

Inspection Plus - an integrated suite of inspection cycles including vector measurement.

Productivity+™ Active Editor Pro - a PC-based software package with GUI, allowing the user to select features directly from an imported CAD model, making the generation of probing cycles even easier.

OMP60 Touch Probe

OMP60 touch probe with optical transmission suitable for medium to large machining and mill-turn centers.

About OMP60

OMP60 probe is part of a new generation of optical transmission machine probes that are compatible with all Renishaw's optical receivers (both legacy and new generation). It brings the benefits of probing to a wide range of machining centers and mill-turn machines, offering users set-up time reductions of up to 90%, reduced scrap, reduced fixture costs, and improved process control.

Renishaw recommends using OMP60 with the OMI-2, OMI-2T and OMM-2 receivers with modulated transmission, although OMP60 is also compatible with existing OMI and OMM / MI 12 receivers, operating in legacy mode. This means that MP7, MP8, MP9 and MP10 users can upgrade to OMP60 and benefit from its innovative features.

Compact probe, measuring Ø63 mm x 76 mm long

360º infra-red transmission with 6 m typical operating range

Rejection of optical interference when used with OMI-2, OMI-2T, OMM-2

Simple installation and configuration

Multiple switch-on/switch-off methods

Backward compatible with existing Renishaw receivers

Uses readily-available AA batteries

OMP60 Software options

The following software packages can be used to program probing routines for work piece set-up and inspection on CNC machining centers

•EasyProbe - entry-level package for simple work piece set-up

•Inspection - basic set-up and work piece inspection cycles, with automatic update of offsets

•Inspection Plus - an integrated suite of inspection cycles including vector measurement

•Productivity+™ Active Editor Pro - a PC-based software package with GUI, allowing the user to select features directly from an imported CAD model, making the generation of probing cycles even easier.

OMP400 Compact High Accuracy Touch Probe

Ultra compact high-accuracy 3D measurement touch probe for small to medium sized machining centres.

About OMP400

The OMP400 is an ultra compact probe, ideally suited to small to medium machining centers. It combines the miniaturization of the highly successful OMP40 probe with new advances in strain gauge technology, pioneered by Renishaw's high accuracy MP700 probe.

Strain gauges attached to the structure measure the smallest of stylus motions, allowing for a very sensitive system.

The innovative RENGAGE™ technology built into the OMP400 brings unrivalled performance in terms of 3D measurement. Use OMP400 with Renishaw OMV for advanced on-machine verification when machining contoured surfaces and complex shapes.

OMP400 Feature and benefits

· Patented RENGAGE™ technology brings unrivalled performance in terms of 3D measurement.

· Increased stylus lengths can be supported without a significant decrease in probe performance

· Compatible with all existing Renishaw optical receiver interfaces (modulated: OMI-2T, OMI-2C, OMI-2 and OSI/OMM-2; legacy: OMI)

· The OMP400 sets new standards for reliability and, sealed to IPX8, OMP400 is designed to resist the harshest machine conditions

OMP400 Software options

The following software packages can be used to program probing routines for work piece set-up and inspection on CNC machining centres

· EasyProbe - entry-level package for simple work piece set-up

· Inspection - basic set-up and work piece inspection cycles, with automatic update of offsets

· Inspection Plus - an integrated suite of inspection cycles including vector measurement

· Productivity+ Active Editor Pro - a PC-based software package with GUI, allowing the user to select features directly from an imported CAD model, making the generation of probing cycles even easier.

RMP40 Compact Touch Probe

Renishaw's smallest probe with frequency hopping radio transmission.

RMP40 is a new addition to Renishaw's inspection probe family. This is Renishaw's smallest frequency hopping spread spectrum (FHSS) radio probe ideal for all sizes of machining centres.

About RMP40

The RMP40 combines the miniaturisation of the OMP40-2 with the radio capability used in the RMP60 and RMP600. It uses the 2.4 GHz frequency band that is compliant with radio regulations worldwide and compatible with any Renishaw RMI or RMI-Q interface/receiver.

With RMP40, machining centres fitted with small HSK and taper spindles can now benefit from FHSS radio transmission technology. It is ideal for multi-axis milling applications where the line of sight between the inspection probe and interface cannot always be maintained.

Simple set-up

Unlike fixed frequency systems, with the RMP40 there is no need to allocate a specific radio channel.

Compact and robust

The RMP40 is ideal for machines of all sizes and can access surfaces cut with short tools. Its robust stainless steel body makes it suited to the harshest machine environments.

Ideal for retrofit

The RMI or RMI-Q (a combined antenna, interface and receiver) can be positioned anywhere near the machine, resulting in a fast installation.

Frequency hopping spread spectrum transmission

Renishaw's FHSS transmission for probes allows the RMP40 and RMI or RMI-Q to hop frequencies together to provide reliable communications.

Miniaturisation

Miniaturisation of electronics has allowed the development of an ultra-compact radio probe measuring only 40 mm in diameter and 50 mm in length; Renishaw's smallest radio probe.

Simple and safe programming

Patented Trigger Logic™ enables users to configure the system without access to the internals of the probe.

RMP40 Software options

The following software packages can be used to program probing routines for work piece set-up and inspection on CNC machining centres

•EasyProbe - entry-level package for simple work piece set-up

•Inspection - basic set-up and work piece inspection cycles, with automatic update of offsets

•Inspection Plus - an integrated suite of inspection cycles including vector measurement

•Productivity+™ Active Editor Pro - a PC-based software package with GUI, allowing the user to select features directly from an imported CAD model, making the generation of probing cycles even easier.

RMP60 Touch Probe

A touch-trigger probe with radio transmission for communicating with the machine's CNC controller, for component setting/inspection on machining centres.

RMP60 uses a unique frequency hopping spread spectrum (FHSS) radio transmission system that makes it ideal for use on large and 5-axis machines.

About RMP60

RMP60 has been designed to take advantage of the extended battery life and multiple probing capabilities of the RMI-Q whilst maintaining backwards compatibility with the original RMI. About RMP60

As with its predecessor, RMP60 is a component of a radio transmission part probing system, and is ideally suited to large machining centres or where line-of-sight between probe and receiver is difficult to achieve.

RMP60 features an integrated probe module delivering exceptional robustness and generous over travel.

RMP60 complies with FCC regulations and operates in the 2.4 GHz band. It delivers interference-free transmission through the use of FHSS (frequency hopping spread spectrum). This allows many systems to operate in the same machine shop without risk of cross-talk.

The RMI-Q integrated interface/receiver is used to communicate between the RMP60 probe and the machine control.

The probe may be activated by RF signal initiated by an M-code, spinning or shank switch.The probe can be used alone or as part of a larger system comprised of multiple radio spindle probes and/or tool setters to function with a single RMI-Q.

RMP60 is also backward compatible with the RMI.

RMP60 Feature and benefits

Proven kinematic design

Secure frequency hopping spread spectrum (FHSS)

Globally recognised 2.4 GHz waveband - compliant with radio regulations in all major markets

Compact design

Various activation options and adjustable trigger force

1.00 μm 2σ repeatability

RMP60 Software options

The following software packages can be used to program probing routines for work piece set-up and inspection on CNC machining centres

EasyProbe - entry-level package for simple work piece set-up

Inspection - basic set-up and work piece inspection cycles, with automatic update of offsets

Inspection Plus - an integrated suite of inspection cycles including vector measurement

Productivity+ Active Editor Pro - a PC-based software package with GUI, allowing the user to select features directly from an imported CAD model, making the generation of probing cycles even easier.

Renishaw OMV - A PC-based software package for verification of complex parts and live data capture to PC during probing for instant feedback on component quality

RMP600 High Accuracy Touch Probe

About RMP600

The Renishaw RMP600 is a compact, high accuracy touch probe with radio signal transmission, offering all the benefits of automated job set-up, plus the ability to measure complex 3D part geometries on all sizes of machining centers including 5-axis machines.

The RMP600 successfully combines the patented RENGAGE™ strain gauge technology with the unique frequency hopping radio transmission system from the RMP60.

Strain gauges attached to the structure measure the smallest of stylus motions, allowing for a very sensitive system.

This innovative RENGAGE™ technology built into the RMP600 brings unrivalled performance in terms of 3D measurement. Use the RMP600 with Renishaw OMV for advanced on-machine verification when machining contoured surfaces and complex shapes.

The 2.4 GHz frequency band is compliant with radio regulations in the EU, USA, Japan, Canada, Switzerland, Australia, New Zealand, Taiwan, India, Indonesia, South Korea, Malaysia, Singapore and China.

RMP600 Feature and benefits

Patented RENGAGE™ technology gives very low and highly consistent contact forces as well as Sub micron 3D performance on contoured surfaces

Increased stylus lengths can be supported without a significant decrease in probe performance

Frequency hopping spread spectrum (FHSS) transmission means that once partnered, the RMP600 and RMI or RMI-Q hop frequencies together to provide reliable communications

The RMP600 utilizes accelerometers to detect shock and motion to assess whether stylus forces are due to valid triggers or high speed acceleration

Multiple probe mode is available on RMP600 to allow the use of many different probes with the same RMI-Q receiver

3D performance is ideal for the calibration and mapping of 5-axis machines

RMP600 Software options

The following software packages can be used to program probing routines for work piece set-up and inspection on CNC machining centres

EasyProbe - entry-level package for simple work piece set-up

Inspection - basic set-up and work piece inspection cycles, with automatic update of offsets

Inspection Plus - an integrated suite of inspection cycles including vector measurement

Productivity+ Active Editor Pro - a PC-based software package with GUI, allowing the user to select features directly from an imported CAD model, making the generation of probing cycles even easier.

Renishaw OMV - A PC-based software package for verification of complex parts and live data capture to PC during probing for instant feedback on component quality.

MP250 touch probe for grinding machines

The world’s first strain gauge based inspection probe for grinding machines, using Renishaw’s patented Rengage™ technology.

About the MP250

The Renishaw MP250 is an ultra compact touch probe for grinding machines that sets new standards for the precision measurement of 3D part geometries, whilst offering all the standard probing benefits of reduced set-up times, reduced scrap and improved process control.

The MP250 uses a hard-wired connection to the machine control via the specially designed HSI interface.

It offers a truly unrivalled combination of size, accuracy, reliability

and robustness that will benefit its users through reduced set-up

times, reduced scrap and improved process control.

The MP250 can also be used with Renishaw's HPGA

(High Precision Generic Arm).

MP250 Feature and benefits

High accuracy: Patented Rengage™ strain gauge technology with ultra-low pretravel variation provides high accuracy, even when the application requires long styli.

Highly repeatable: Improved repeatability in all probing directions compared to standard probes.

Ultra compact: Measuring only Ø25 mm x 40 mm long, the MP250 is ideal for grinding machine applications with restricted space.

Robust and reliable: Renishaw's MP250 sets new standards for reliability and is designed to resist the harshest machine conditions.

Job Contact Probes

Job contact probes have been designed for use on manual machines and are ideal for workpiece set-up and simple inspection.

About JCP

The JCP1, available with metric and imperial shanks, uses electrical conductivity to sense contact with a metallic workpiece. An LED is illuminated when the stylus touches the surface.

The JC30C variant provides a cable connection to digital readout counters with touch sensor inputs.

JCP Specifications Table

Specification

Sense directions: ±X, ±Y, +Z

Unidirectional repeatability (max 2 sigma at stylus tip): 1.0 µm (0.00004 in)

Weight: 240 g (8.5 oz)

Stylus overtravel: XY plane: ±15 mm (±0.59 in) +Z direction: 5 mm (0.20 in)

Stylus dimensions: JC30C / JCP1-M: 42.75 mm x ø6 mm, JCP1-I: 1.68 in x ø0.24 in

Battery: Type: 2 x LR1 1.5 V Life: 30 hours

Sealing: IP 44

Shanks: JC30C: ø16 mm, JCP1-M: ø20 mm, JCP1-I: ø0.75 in